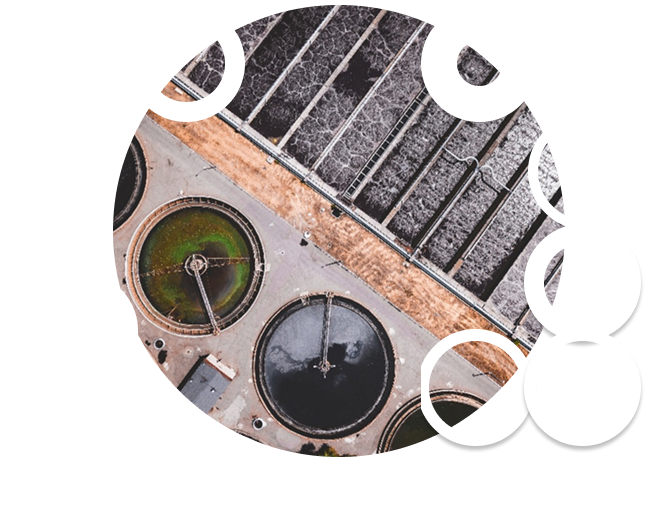

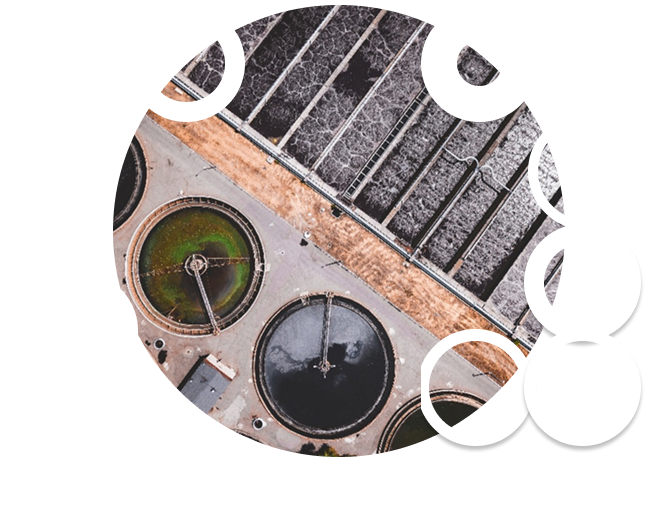

Reclaimed Water Treatment

AQFILM Membrane Materials Company's membrane product portfolio includes nanofiltration and ultrafiltration solutions, tailored to meet the reclaimed water requirements of diverse industries.

AQFILM Membrane Materials Company's membrane product portfolio includes nanofiltration and ultrafiltration solutions, tailored to meet the reclaimed water requirements of diverse industries.

China's reclaimed water utilization has grown rapidly. From 2012 to 2022, the national reclaimed water utilization increased from 3.585 billion cubic meters to 15.09 billion cubic meters, and the reclaimed water utilization rate grew from 8.82% to 20.44%. With population growth and accelerated urbanization, global water shortages are spreading, and water resources are increasingly strained in many regions. Strict environmental policies require reducing water pollution from sewage discharge, while reclaimed water reuse can reduce pollutant emissions and alleviate impacts on water environments around cities. For industrial users, using reclaimed water for production can reduce costs and achieve greater benefits. With our nanofiltration (NF) and ultrafiltration (UF) technologies, we can achieve the following goals:

Enhancing Water Quality Stability: Ultrafiltration removes colloids and macromolecular organic matter from water, reducing the chemical activity of these substances and lowering the chemical oxygen demand (COD) and biochemical oxygen demand (BOD), thus making the water quality more stable.

Expanding the Application Scope of Reclaimed Water: The water quality of reclaimed water treated by nanofiltration (NF) and ultrafiltration (UF) is significantly improved, meeting the water requirements of more sectors. In the industrial field, it can be used as process water or cooling water in production links with high water quality requirements, such as electronic chip manufacturing, chemical engineering, and pharmaceuticals.

Reducing Treatment Costs: However, in the long run, its high-efficiency purification capability and good water quality stability can reduce the costs of subsequent treatment processes.

Large amounts of wastewater are generated during petroleum refining, which exhibit the following characteristics:High water volume: Petroleum refining produces substantial wastewater, including production wastewater, cooling water, and other process water.Complex water quality: The refining process involves difficult-to-treat substances such as mineral oils and polycyclic aromatic compounds (PAHs), which are difficult to degrade.High pollutant concentration: Certain pollutants in petroleum refining wastewater reach high concentrations.High temperature: Wastewater generated during refining has elevated temperatures. High-temperature wastewater can slow the metabolic rate and growth of microorganisms in subsequent biochemical treatment, and excessively high temperatures may even be lethal to microorganisms, impairing the wastewater treatment efficiency of the biochemical system.These characteristics make the treatment of petroleum refining wastewater particularly challenging and critical. When treated petrochemical wastewater is reused as reclaimed water, it still faces issues such as water quality fluctuations, oil content, and refractory pollutants. In the on-site advanced reuse workshop, the original ultrafiltration membrane system experienced significant filament breakage after a period of operation, directly affecting the performance of the subsequent reverse osmosis system.

The highly polluting characteristics of textile dyeing and printing wastewater have long drawn attention from the environmental protection industry. During the production process of converting textile raw materials into finished textiles, over 8,000 types of environmentally harmful chemicals are generated. Textile dyeing and printing wastewater exhibits the following characteristics:Large water volume: The dyeing and printing process produces substantial wastewater, primarily due to the high water consumption in cleaning and rinsing procedures.High organic pollutant content: The wastewater contains organic pollutants such as dyes, sizing agents, auxiliaries, oil agents, acids/bases, fiber impurities, sand-like substances, and inorganic salts, resulting in extremely high concentrations of organic matter.High chromaticity: Due to the large amount of dyes in the wastewater, it exhibits a deep color, which adds extra difficulty to wastewater treatment.High alkalinity: The textile dyeing and printing process uses a large amount of alkaline substances, making the wastewater typically alkaline.Wide pH variation: Due to the presence of various chemical substances in the wastewater, its pH value may fluctuate significantly.Drastic water quality changes: Each process in textile dyeing and printing may generate wastewater with different properties, and the mixing of these wastewaters can lead to drastic changes in water quality.Under such complex water quality conditions, the anti-fouling and cleaning-resistant properties of ultrafiltration membranes for reclaimed water are extremely high.