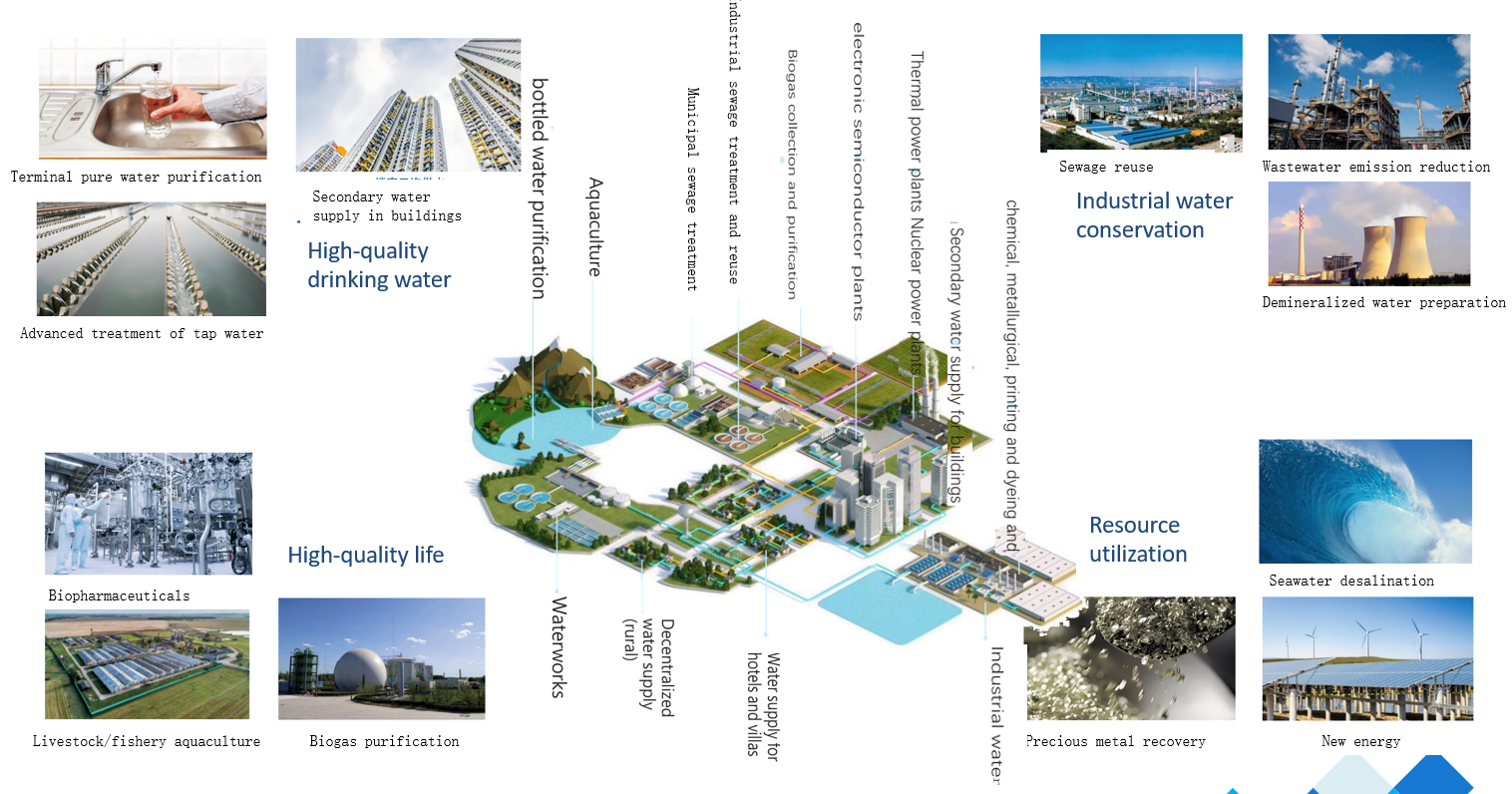

Application Scenarios

With their superior performance, AQFILM's nanofiltration and ultrafiltration products are widely applicable to various scenarios.

With their superior performance, AQFILM's nanofiltration and ultrafiltration products are widely applicable to various scenarios.

An industrial park located in Ordos City, Inner Mongolia, primarily focuses on modern coal chemical industry, new material industry, and fine chemical industry in its development zone. As industrial water accounts for a high proportion of the total water consumption while water resources are relatively scarce in the park, the reuse of coking wastewater can recycle treated water for industrial production. This approach improves water resource utilization and alleviates the pressure of water shortage.

The original desalinated water production capacity of the enterprise's system was 300 TPH. Due to increased production demand for desalinated water, renovations were required within the original workshop to achieve a desalinated water output of 1,000 TPH. Meanwhile, the project faced technical challenges such as low reuse water utilization rate in the industrial desalinated water system and high hardness in reverse osmosis concentrate, which posed significant treatment difficulties. The client required that system recovery rate be increased by over 20% from the original level without expanding the footprint.

The company is a publicly listed Taiwanese enterprise with the most complete generation production lines ranging from G3.5, G4, G4.5, G5, G6, G7.5, G8.5 to G8.6. It is the world’s only integrated display provider with complete production capabilities for large, medium, and small-sized LCD panels and touch panels across the entire supply chain.For its liquid crystal panel washing wastewater treatment system, the MRB process technology is adopted. After A²O biochemical treatment, the wastewater enters the MBR membrane tank. The effluent from the MBR membrane tank directly feeds into the RO system for reuse.

The project employs the Canadian DAGUA process, which utilizes minimal or no chemical additives to deliver original-ecology, healthy, and safe drinking water treatment. This approach truly ensures a non-toxic and harmless treatment process, with the effluent meeting direct drinking water standards.The Canadian DAGUA process relies on micro-bubble ozone + oxidation-resistant ultrafiltration membranes as its core. This imposes strict performance requirements on the supporting ultrafiltration membranes: the water entering the membranes contains an ozone concentration of 0.3–0.5 mg/L. Conventional ultrafiltration membranes are prone to oxidation and degradation at this ozone concentration, with a service life of less than 2 years.

A waterworks in Tianjin is located in Wuqing District, Tianjin, with a water production scale of 30,000 tons per day. The water sources are the water from the East Route of the South-to-North Water Diversion Project and the Luanhe River. When surface water is used as drinking water, it faces biological safety issues such as "two worms" (Giardia and Cryptosporidium), algae pollution, and algal toxins. This project adopts a new high-efficiency short-process technology of ozone + ultrafiltration from Canadian Dugua, which requires the ultrafiltration membrane to have continuous oxidation resistance to ozone, while ensuring the effective removal of "two worms" in the water and the stable supply of produced water quality, so as to realize a short-process high-quality drinking water demonstration project with ultrafiltration as the core process.

Weihai a Certain Power Generation Seawater Desalination Project (Phase I) uses seawater as the water source. Through the treatment process of V-type filter tank + ultrafiltration + reverse osmosis, the desalinated seawater is supplied as municipal drinking water to the municipal pipeline network. The construction scale of Phase I is 30,000 tons/day of desalinated water, and the internal pressure type ultrafiltration membrane is selected for the filtration mode.The seawater desalination system generally operates when the water temperature is 2-3℃ in winter. Low temperature increases the viscosity coefficient of water, which enhances the membrane filtration resistance. Moreover, temperature has a significant impact on the water production flux of the membrane. Therefore, the key to this project is to ensure full-load long-term stable operation under low-temperature conditions.

The highly polluting characteristics of textile dyeing and printing wastewater have long drawn attention from the environmental protection industry. During the production process of converting textile raw materials into finished textiles, over 8,000 types of environmentally harmful chemicals are generated. Textile dyeing and printing wastewater exhibits the following characteristics:Large water volume: The dyeing and printing process produces substantial wastewater, primarily due to the high water consumption in cleaning and rinsing procedures.High organic pollutant content: The wastewater contains organic pollutants such as dyes, sizing agents, auxiliaries, oil agents, acids/bases, fiber impurities, sand-like substances, and inorganic salts, resulting in extremely high concentrations of organic matter.High chromaticity: Due to the large amount of dyes in the wastewater, it exhibits a deep color, which adds extra difficulty to wastewater treatment.High alkalinity: The textile dyeing and printing process uses a large amount of alkaline substances, making the wastewater typically alkaline.Wide pH variation: Due to the presence of various chemical substances in the wastewater, its pH value may fluctuate significantly.Drastic water quality changes: Each process in textile dyeing and printing may generate wastewater with different properties, and the mixing of these wastewaters can lead to drastic changes in water quality.Under such complex water quality conditions, the anti-fouling and cleaning-resistant properties of ultrafiltration membranes for reclaimed water are extremely high.

Large amounts of wastewater are generated during petroleum refining, which exhibit the following characteristics:High water volume: Petroleum refining produces substantial wastewater, including production wastewater, cooling water, and other process water.Complex water quality: The refining process involves difficult-to-treat substances such as mineral oils and polycyclic aromatic compounds (PAHs), which are difficult to degrade.High pollutant concentration: Certain pollutants in petroleum refining wastewater reach high concentrations.High temperature: Wastewater generated during refining has elevated temperatures. High-temperature wastewater can slow the metabolic rate and growth of microorganisms in subsequent biochemical treatment, and excessively high temperatures may even be lethal to microorganisms, impairing the wastewater treatment efficiency of the biochemical system.These characteristics make the treatment of petroleum refining wastewater particularly challenging and critical. When treated petrochemical wastewater is reused as reclaimed water, it still faces issues such as water quality fluctuations, oil content, and refractory pollutants. In the on-site advanced reuse workshop, the original ultrafiltration membrane system experienced significant filament breakage after a period of operation, directly affecting the performance of the subsequent reverse osmosis system.

Located in the Hengduan Mountains and the Sanjiang River Basin, Changdu County in Tibet lies in eastern Tibet, serving as a vital junction connecting Tibet with Sichuan, Qinghai, and Yunnan. It is a necessary passage for both the Sichuan-Tibet and Yunnan-Tibet highways, as well as a key location on the "Tea-Horse Ancient Road." Despite its beautiful landscape, the daily drinking water for 1,700 teachers and students at the local No. 2 Primary School and No. 1 Kindergarten has become a major challenge. To address this and ensure they have access to healthy drinking water, the Industrial Water Treatment Professional Committee launched the "Sweet Dew Nourishing Young Shoots Public Welfare Initiative," aiming to solve the daily water challenges for local teachers and students through professional equipment and technology.